Opening the Black Box: Dissecting the BWI MagneRide Damper

Opening the Black Box: Dissecting the BWI MagneRide Damper

The Brutal Simplicity of Modern Electronic Suspension

Prologue: Breaking the Taboo

Editor: Mr. Shimbo, this is quite a niche topic today. We are talking about the BWI MagneRide magnetorheological dampers (MR dampers) used in supercars like Ferrari and Lamborghini. Generally, these are considered “Black Boxes” where the only option upon failure is a complete replacement, correct?

Shimbo: Exactly. Whether you go to a dealer or a specialist shop, the standard procedure is a “Full Assembly Replacement.” The structure is considered too unique and special, effectively making it an “untouchable sanctuary” for mechanics. But that is precisely why SGF needs to make an incision here. As professionals, we cannot handle our customers’ vehicles without understanding the “possibility of repair” and the “truth inside.”

Editor: So, you actually acquired a damper for research and dismantled it?

Shimbo: Yes. I took it completely apart. What I found inside was contrary to its high-tech image. It was an extremely rationalized—and, in a sense, brutal—reality: almost all of the “mechanical intelligence” had been stripped away and relocated into software.

Chapter 1: The “Lump of Iron” (Extreme Rationalization)

Editor: A brutal reality…? Was the inside that complex and bizarre?

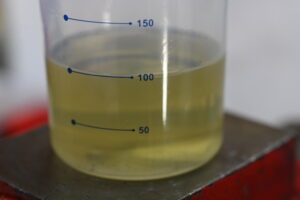

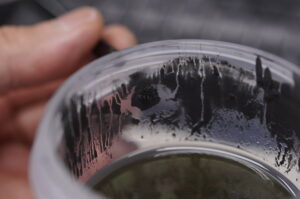

Shimbo: Quite the opposite. It was almost disappointingly empty. There were no “shims” (leaf springs) or “complex orifices (oil passages)” that you would invariably find in conventional dampers. All that came out was a piston—which is essentially a magnetic block with a thick copper coil wound around it—and the sludge-like magnetic fluid.

Editor: Wait, no shims? Then how does it generate damping force?

Shimbo: That is the core of BWI technology. Instead of using mechanical resistance (deflection of shims), it generates resistance by running electricity through the fluid to instantly change its viscosity. Therefore, the hardware structure has been “functionally purified.” (Insert Photo: Simplified piston and coil structure) As you can see from the photos, the piston is truly just an electromagnet.

Editor: I see… So, “simple is amazing”?

Shimbo: “Simple means faster response speed” is the correct interpretation. Since there are no mechanical moving parts, there is essentially zero lag. However, being simple does not necessarily mean “cheap.” I was surprised when I inspected the inside of the disassembled cylinder. Despite moving fluid containing iron powder at high speeds, there was extremely little wear. This is proof that substantial costs are invested in the invisible parts, such as internal coatings and material quality.

Chapter 2: Is Repair Possible?

Editor: If the structure is simple, does that mean the “Overhaul/Repair” that users are desperate for is possible? A full replacement for a Lamborghini can cost an exorbitant amount…

Shimbo: The conclusion is: “Partially, yes. It is possible right now.” First, regarding “Oil (Fluid) Leaks,” which is the most common issue. Although the structure is unique, the logic of the seals is the same as a standard damper. By selecting appropriate sealing materials and refilling the expensive magnetic fluid, physical leaks can be fixed.

Editor: That is great news—especially considering a full set of new dampers can easily run into the tens of thousands of dollars.

Shimbo: Next is “Electrical Trouble.” If the issue is external, such as a severed wire or a faulty connector, this can be diagnosed with a tester and repaired. This is not a black box either.

Editor: What if the coil in the heart of the unit burns out?

Shimbo: That is the current challenge. We have disassembled it and collected data on the coil gauge and resistance values. We analyzed it with our in-house electronics team, and as an actuator, it is a sound design. In other words, “physically rewinding it” is possible. However, the process of rewinding inside the piston and re-sealing it is still in the experimental stage. If we can establish this process, BWI dampers will evolve from disposable parts to “rebuildable components.”

Chapter 3: The Subordination of Hardware and the Dominance of Software

Editor: I see… I didn’t expect SGF to dig that deep. But listening to you, Mr. Shimbo, I get the feeling that “making the object itself seems surprisingly simple.”

Shimbo: That is a sharp intuition. To put it boldly, replicating the hardware (piston and coil) itself wouldn’t be difficult if you have the right equipment. But that is exactly when you realize it: “The difficulty of technology has shifted from mechanism to logic (control).”

Editor: What do you mean?

Shimbo: In conventional dampers, the correct answer for physics (damping characteristics) was pre-programmed into the hardware—the stack of shims. Even without electricity, they were almost “autonomous machines” that did a good job on their own. In contrast, a BWI damper is just a lump of iron without electricity. “What viscosity is needed right now?” “What should the posture be 0.01 seconds later?” Everything must be constantly managed by “Algorithms and Commands (Software).”

Editor: Ah… So the simpler the hardware becomes, the smarter the software driving it must be.

Shimbo: Exactly. The disassembled lump of iron quietly told the story of how modern car manufacturing has irreversibly shifted from being “Mechanically-led” to “Software-led.”

Notes on Inquiries & Scope

Important Notice for International Readers

The primary purpose of this article is to share technical insight into BWI MagneRide dampers with engineers and suspension specialists around the world. It is not intended as a sales pitch or service offer for overseas customers.

At this time, SGF Japan does not accept overhaul or repair commissions for BWI dampers from outside Japan. If you are reading this outside Japan, please treat this report purely as a technical reference.

For Domestic (Japan) Industry Professionals

Within Japan, SGF provides technical consultation and overhaul services for BWI magnetorheological dampers on a B2B basis only (automotive repair shops, dealers, and specialist workshops).

We can support:

-

Cases where OEM supply has ended or replacement costs are prohibitive

-

Diagnostic separation of electronic vs. mechanical faults

-

Feasibility studies for function recovery via overhaul

Please note: We do not accept direct requests from individual owners. Kindly contact us through the workshop or dealer that services your vehicle.

Contact (Japan Only)

-

Phone (B2B only): +81-90-3316-5306

-

Email: sgf@sgfacendo.com

-

Web form: https://sgfacendo.com/contact/